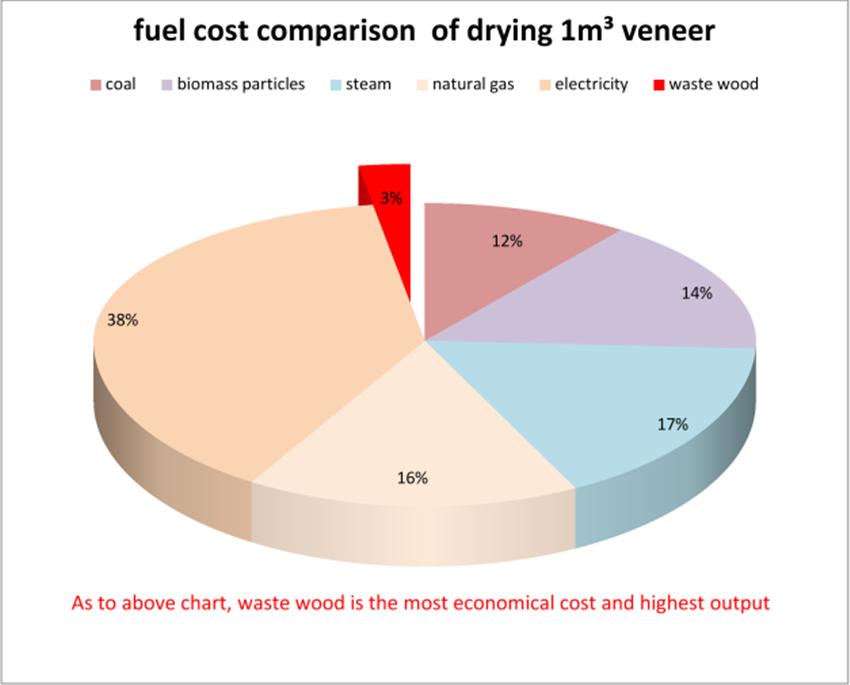

Shine roller veneer drying technology utilizes the latest international technology of pressurized contact veneer drying, which has the advantages of simple operation, safety and practicality, stable operation, easy maintenance, heat pressing- leveling--drying once completed, etc. The cyclic utilization of hot air has greatly reduced the operating costs of enterprises, improved the quality of sheet materials and increased the production volume. The roller plays a role in ironing the veneer. After the veneer is dried, the veneer is flat and the moisture content is relatively uniform. When the veneer is located between two roller sets, the lateral direction can be freely contracted, the occurrence of cracks is reduced, and the drying quality is good. The heat dissipation process is carried out in a flat state. In the benign physical process of wood shrinkage, the veneers do not warp and deform, the breakage rate is low, and the finished products rate is high. Wood panel veneer dryer of Shine can burn the waste wood directly and other biomass material and save the energy cost greatly for the users.

Parameter Model |

DHS20M

| DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 1 | 1 | 1 | 1 | 1 | 1 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 0.5-0.65 | 0.65-0.8 | 0.8-1 | 1-1.2 | 1.15-1.35 | 1.3-1.5 |

Heat exhaustion(10000 kcal) | 17.5-23 | 28-35 | 35-42 | 40.25-47.25 | 45.5-52.5 | |

Traction motor power(kw) | 7.5 | 7.5 | 5.5 | 5.5 | 5.5 | 5.5 |

Hot air fan power (kw) | 7.5*4 | 7.5*5 | 7.5*6 | 7.5*7 | 7.5*8 | 7.5*9 |

Air cooling fan power(kw) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Total power (kw) | 45 | 52.5 | 58 | 65.5 | 73 | 80.5 |

Overall size LxWxH(m) | 20*4.5 | 24*4.5 | 28*4.5 | 32*4.5 | 36*4.5 | 40*4.5 |

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd