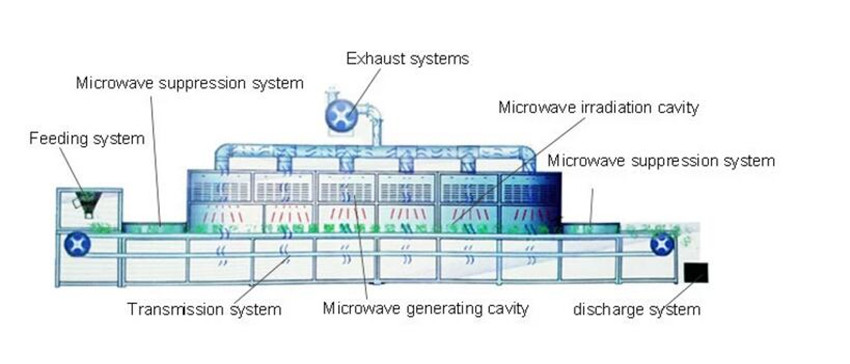

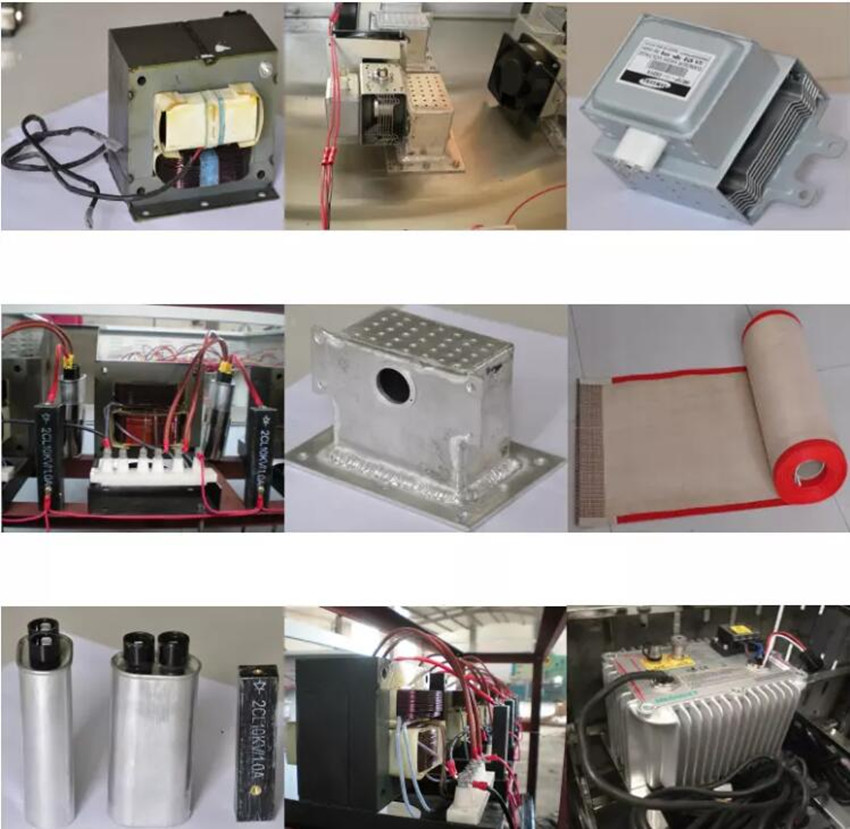

Microwave drying &sterilization equipment is used under the effect of microwave electromagnetic field, and the processed materials are evenly heated from outside to internal and dry and dehydrated. At the same time, it is sterilizing under the dual action of microwave heat effect and non thermal effect. Therefore, the material has completed the sterilization process at the same time. The microwave drying sterilization equipment is automatic. The temperature control system, automatic control microwave density system, automatic alarm system, video surveillance system, transmission belt automatic deviation system, transmission frequency control system, material control system, PLC control system and so on. Microwave tube adopts Japanese Panasonic brand, transformer can choose oil immersion cooling, air cooling and self cooling, which can ensure the continuous operation of equipment for 24 hours. Microwave drying sterilization equipment adopts streamlined operation, simple operation, high yield, environmental protection, fast heating speed, uniform heating and good controllability.

The drying speed is fast: the wood moisture content is reduced from 35% to 20% drying time is about 10 ~ 15 minutes, which is 20 ~ 30 times that of steam drying process. However, it must be noted that with the increase of microwave power, the drying speed will be faster, at the same time, the internal temperature of wood will rise sharply, and the wood will burst when the moisture is vaporized and desiccated too fast. Therefore, the processing speed should not be pursued too much, and larger microwave power should be used.

The efficiency of microwave drying wood is high: when the wood is generally treated, the standard of water lifting rate is 1 kilowatt per hour microwave power is used to desiccate the material and remove 1 kg of moisture. The actual dehydration rate is about 0.8-1.0 kg per hour due to the difference of tree species and wood hardness. But in the same tree species, the drying effect of wood along the fiber direction is obviously different, the dehydration rate of the short fiber length is higher, the contrary is lower. Because of the season, the humidity of the weather will also affect the dehydration rate, should pay more attention to the application.

The quality of wood dried by microwave is good: microwave drying of wood materials has strong permeability and heating selectivity, so the shrinkage rate of the internal and external ends and intermediate fibers of wood is basically consistent during the drying process. Therefore, the wood cracking and deformation is small. However, the traditional drying methods will deform, crack, mildew, metamorphism and other phenomena, seriously affect the quality of wood, resulting in a large number of scraps. The utilization rate of wood can be increased by about 5% by microwave drying, so a large amount of wood can be saved.

Microwave drying of wood is not affected by outside climatic conditions: when microwave drying equipment is used, it is not affected by changes in external natural conditions, and it takes up to a year or years for conventional methods to adopt natural drying, Also occupy a large production base, spend more labor handling, increase production costs.

Microwave drying of wood kills pests: while drying wood by microwave, the harmful borers in wood can be killed, which is due to the strong resonance effect between microwave electromagnetic energy and water molecules in wood materials. Kill all the harmful borers, eggs, and larvae inside the parasitic wood. When the temperature is 7080 degrees, it takes 2 minutes to solve the problem

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd