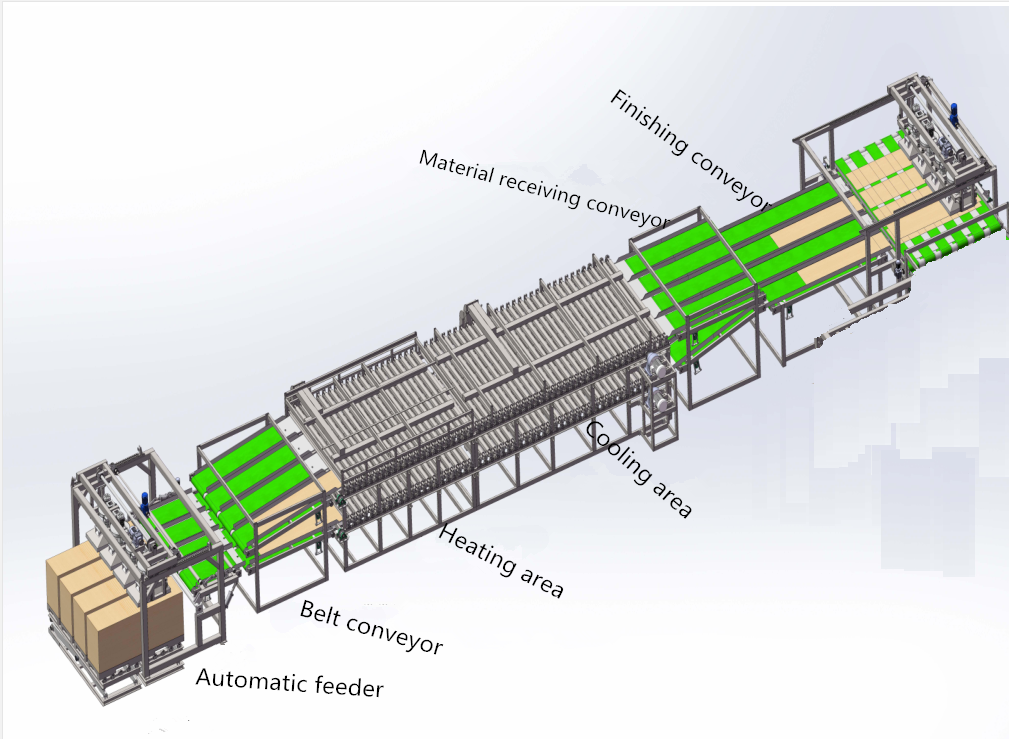

Shine biomass veneer dryer is a new engergy saving dryer model. The heat source is biomass burner instead of steam or oil boiler. The veneer roller dryer is used for drying peeled veneer or sliced veneer in the veneer production line. The veneer drying machine consists of feeding, heating or drying section, cooling section and unloading or discharging section as well as the veneer collection system. The veneer dryer size is customized according to the production capacity, veneer size, moisture content and space, in order to improve productivity with lowest investment.

Technical Parameter for Veneer Roller Dryer in Plywood Production Line

Parameter Model |

DHS20M

| DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 2 | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 0.8-1.1 | 1.1-1.4 | 1.5-1.8 | 1.8-2.2 | 2-2.5 | 2.4-2.7 |

Heat exhaustion(10000 kcal) | 28-38.5 | 38.5-49 | 52.5-63 | 63-77 | 70-87.5 | 84-94.5 |

Traction motor power(kw) | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 |

Hot air fan power (kw) | 11*4 | 11*5 | 11*6 | 11*7 | 11*8 | 11*9 |

Air cooling fan power(kw) | 11 | 11 | 11 | 11 | 11 | 11 |

Total power (kw) | 66 | 77 | 88 | 99 | 110 | 121 |

Overall size LxWxH(m) | 20*4.5 | 24*4.5 | 28*4.5 | 32*4.5 | 36*4.5 | 40*4.5 |

Company Introduction

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd