Veneer Roller Dryer and Its Heat Source

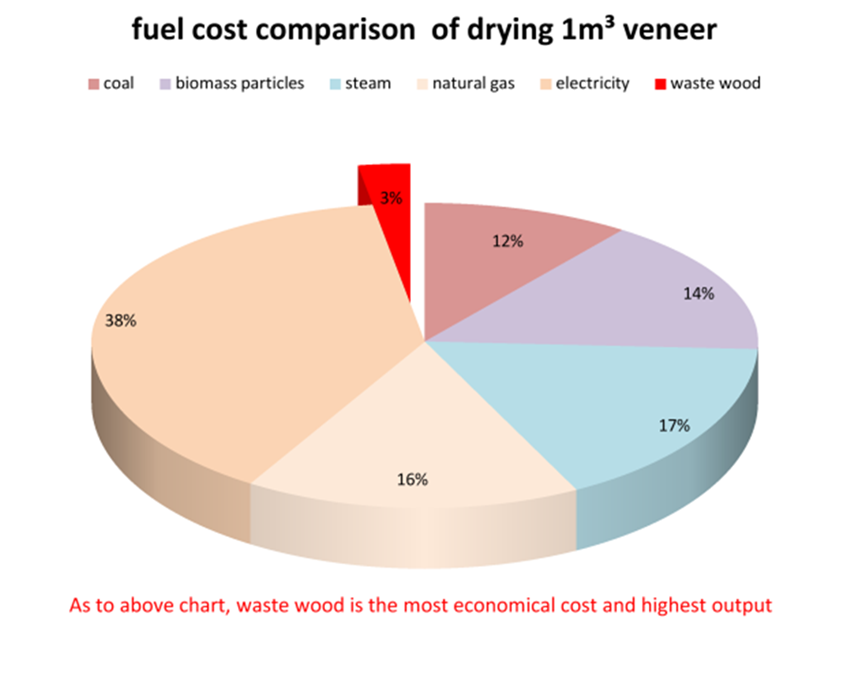

The temperature inside the biomass burner is about 1156℃ which is much higher than the steam boiler. And the temperature inside the dryer is 140-200℃(adjustable). The higher temperature can ensure the high production capacity. The biomass burner heated veneer roller dryer has the lowest production cost of $6-12/cubic meter including the labor cost, fuel cost and electricity power. In addition, the veneer roller dryer adopts advanced technology with the merits of high productivity, energy efficiency, and environmental protection for plywood production line. The plywood veneer dryer machine not only solves the key problem of high fuel cost of veneer drying equipment but also solves the serious problem of waste accumulation in wood processing plants. Shine veneer roller dryer can achieve the best veneer drying effect and lowest drying cost.

Parameter Model |

DHS20M

| DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 1 | 1 | 1 | 1 | 1 | 1 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 0.5-0.65 | 0.65-0.8 | 0.8-1 | 1-1.2 | 1.15-1.35 | 1.3-1.5 |

Heat exhaustion(10000 kcal) | 17.5-23 | 28-35 | 35-42 | 40.25-47.25 | 45.5-52.5 | |

Traction motor power(kw) | 7.5 | 7.5 | 5.5 | 5.5 | 5.5 | 5.5 |

Hot air fan power (kw) | 7.5*4 | 7.5*5 | 7.5*6 | 7.5*7 | 7.5*8 | 7.5*9 |

Air cooling fan power(kw) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Total power (kw) | 45 | 52.5 | 58 | 65.5 | 73 | 80.5 |

Overall size LxWxH(m) | 20*4.5 | 24*4.5 | 28*4.5 | 32*4.5 | 36*4.5 | 40*4.5 |

Company Information

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd