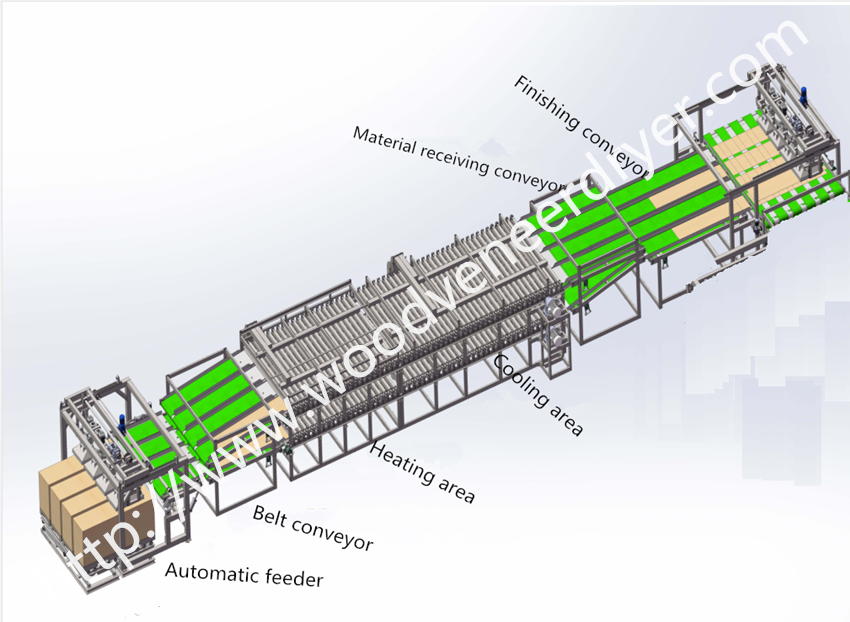

Steam heating roller veneer dryer adpots steam as heating source . it is mainly used by the user who have steam source from electricity power plant or other source. this kind of roller veneer dryer can save feul cost for the user and also can protect enviornment greatly . DHS52M roller core veneer plywood drying machinery is normall model veneer drying machine for plywood produciton . The capacity is about 50cbm per day for different moisture veneers. Roller core veneer dying machinery is the main equipment for the production of plywood, also known as roller veneer dryer. The moisture content of the fresh veneer is very high. The environmental veneer dryer machine is mainly used for the drying of veneers. It is an economical method to reduce the moisture content of the veneer to minimize the loss of the plate and meet the veneer requirements of dry veneer process. Environmental veneer dryer equipment is composed of transmission room, drying room, cooling room and other parts. This equipment highlights less investment and cost-effective advantages. It defines the new concept of high-tech products. This environmental veneer dryer effectively solves the difficult issues such as hard to dry, long drying cycle, uneven drying, easy to crack, deformation and low yield and other problems during the drying process.

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Deck | 1 | 1 | 1 | 1 | 1 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 1.5-1.7 | 1.65-1.8 | 1.7-1.9 | 1.8-2 | 1.9-2.2 |

Heat exhaustion(10000 kcal) | 52.5-59.5 | 57.75-63 | 59.5-66.5 | 63-70 | 66.5-77 |

Traction motor power(kw) | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Hot air fan power (kw) | 7.5*10 | 7.5*11 | 7.5*11 | 7.5*12 | 7.5*13 |

Air cooling fan power(kw) | 7.5 | 7.5 | 7.5*2 | 7.5*2 | 7.5*2 |

Total power (kw) | 88 | 97.5 | 105 | 112.5 | 120 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

1. The veneer after drying by Shine veneer dryer is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect.

3.Shine roller veneer dryer covers a small area, less ancillary equipment, convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4.Standardized production models, can make different sections or decks according to different capacity requirements.which can meet different customers' requirements.

Copyright By © Shandong Shine Machinery Co.,Ltd