Built-in combustion furnace roller veneer dryer is one kind of Shine roller veneer drying machine . the capacity for single deck veneer dryer is from about 16 cbm to 50 cbm per day . the length can be 20-60m .also we can design special models according to customer's special requirements. the main features of the built-in combustion furnace roller veneer drying machine are that the furnace is built in toghether with the microwave dryer body. no need extra burner . it can not only save area for the users , but can save the equipment cost also . the cost is lower compared to external burner. the heating material for the built-in combustion furnace veneer dryer can be coal, waste wood and others.The plywood veneer dryer line produced by Shandong Shine Machinery Co., Ltd. is widely used in flatting drying of high-grade plywood, multi layer board and architectural core face veneer. Except for the built-in combustion furnace roller veneer dryer ,Shine Machinery also produce other types veneer dryer, such as biomass roller veneer dryer, steam heating veneer drying machine,heat conduction oil veneer dryer .electricity heating veneer dryer line and etc.

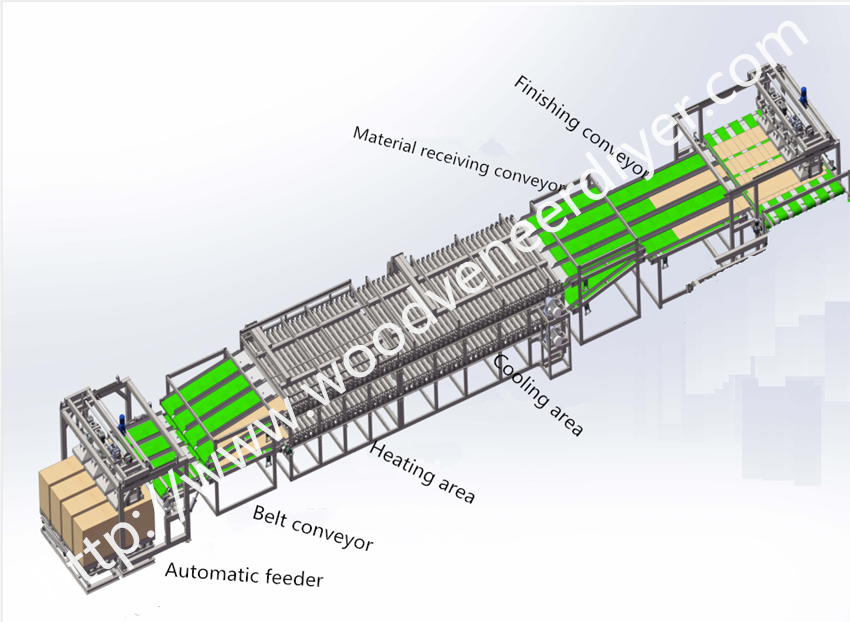

operating system:The planer (rotary) cutting veneer is fed into the inlet of the jet roller type veneer dryer, and through the relative rotation of several pairs of upper and lower rollers located inside the dryer, the planing veneer moves forward in a predetermined direction, and in the course of the veneer travel,The hot wind of 110-150 degrees Celsius is sprayed vertically to the upper and lower surfaces of the veneer by the nozzle located between the two pairs of rollers with the wind speed of V=1.5M/S. Under the control of the electronic control system, the optimal travel speed is adjusted to achieve the best drying effect.And the uneven veneer, after the relative rotation of the upper and lower rollers,can reach the effect of ironing veneer.

Heat medium obtain types of Jet Roller veneer Dryer :External Type Biomass Burner, Built-in Burner, Hot blast stove Type: the air injection roller type veneer dryer produced by our factory is specially equipped with energy saving and high efficiency hot blast stove considering that the user does not have the choice of steam type machine.The working principle of the hot blast stove is to produce high temperature by burning waste wood or raw coal from the veneer factory through the hot blast stove. Under the action of a high speed rotating fan in the machine, the hot air is sent to the nozzle located in the machine and then the strong injection is passed through the nozzle.Spray the hot air onto the upper and lower surfaces of the veneer in operation, so as to achieve the effect of drying.

Electronic control system:The frequency conversion control system of the jet roller type veneer dryer adjusts the travel speed according to the thickness and moisture content of the veneer in order to achieve the best drying effect.

Dehumidifying system :The dehumidifying system of the ejector roller veneer dryer is operated by a number of dehumidify holes located in the machine, through the adjustment of the valve, and adopt the function of the automatic damp removing system or the mechanical strong dehumidifying system to achieve the best effect of humidity discharge.

Sealing thermal insulation system: In order to achieve best drying efficiency of the ejector roller veneer dryer, the shell of the machine is insulated by the shell with thickness of 75MM-100MM, so as to achieve the heat in the machine and no loss of air volume.Thus to achieve the most ideal sealing and insulation effect.

Parameter Model |

DHS20M

| DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 1 | 1 | 1 | 1 | 1 | 1 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 0.5-0.65 | 0.65-0.8 | 0.8-1 | 1-1.2 | 1.15-1.35 | 1.3-1.5 |

Heat exhaustion(10000 kcal) | 17.5-23 | 28-35 | 35-42 | 40.25-47.25 | 45.5-52.5 | |

Traction motor power(kw) | 7.5 | 7.5 | 5.5 | 5.5 | 5.5 | 5.5 |

Hot air fan power (kw) | 7.5*4 | 7.5*5 | 7.5*6 | 7.5*7 | 7.5*8 | 7.5*9 |

Air cooling fan power(kw) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Total power (kw) | 45 | 52.5 | 58 | 65.5 | 73 | 80.5 |

Overall size LxWxH(m) | 20*4.5 | 24*4.5 | 28*4.5 | 32*4.5 | 36*4.5 | 40*4.5 |

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Deck | 1 | 1 | 1 | 1 | 1 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 1.5-1.7 | 1.65-1.8 | 1.7-1.9 | 1.8-2 | 1.9-2.2 |

Heat exhaustion(10000 kcal) | 52.5-59.5 | 57.75-63 | 59.5-66.5 | 63-70 | 66.5-77 |

Traction motor power(kw) | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Hot air fan power (kw) | 7.5*10 | 7.5*11 | 7.5*11 | 7.5*12 | 7.5*13 |

Air cooling fan power(kw) | 7.5 | 7.5 | 7.5*2 | 7.5*2 | 7.5*2 |

Total power (kw) | 88 | 97.5 | 105 | 112.5 | 120 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

Copyright By © Shandong Shine Machinery Co.,Ltd