Veneer Dryers Description

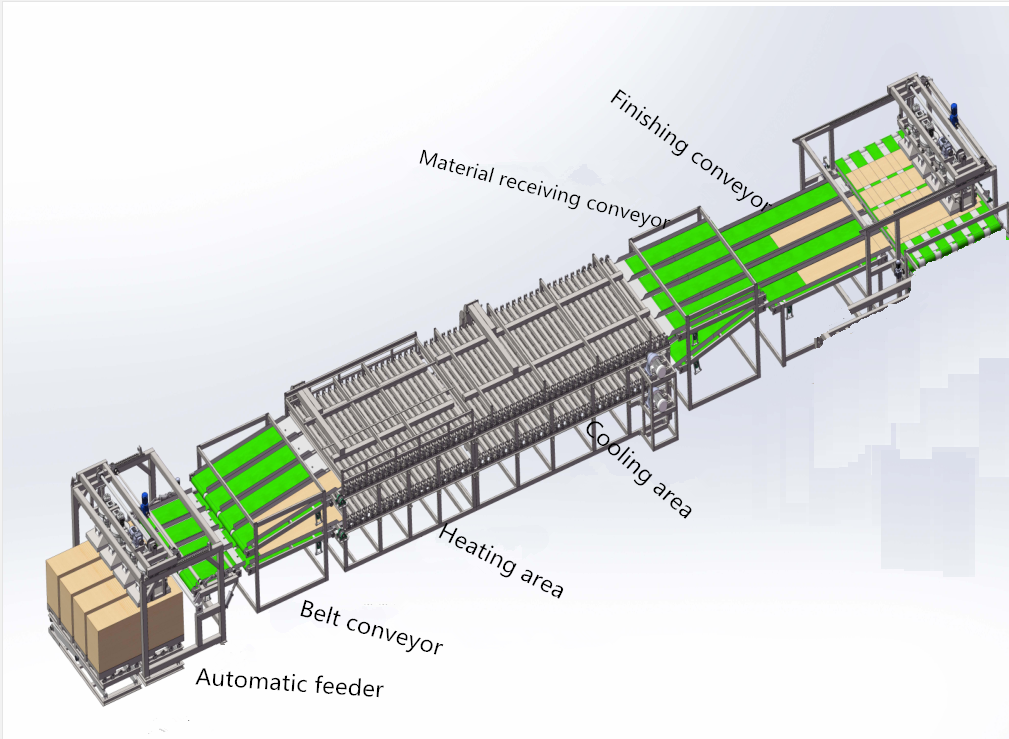

Veneer dryer is ideal for drying wood veneers.Veneer dryer machine can dry veneers of various thickness and various moisture contents.Veneer drying machine is one of the main equipments in plate production. The quality of wood veneer dryer directly affects the quality of veneer and glued products. The design of hot air continuous roller press is based on the most advanced continuous pressure contact veneer drying technology in the world.SHINE heat exchanger adopts step by step heat transfer, and the specifications of each section of the heat exchanger are different, and the hot air in the heat exchanger can be uniformly emitted to the veneer. Our biomass burner for core veneer dryer as patent products,which can use waste wood as fuel and burn all kinds of waste wood directly to reduce fuel cost to the most.Veneer dryers machine offers great advantages over conventional veneer drying systems.

Parameter Model |

DHS20M

| DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 2 | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 0.8-1.1 | 1.1-1.4 | 1.5-1.8 | 1.8-2.2 | 2-2.5 | 2.4-2.7 |

Heat exhaustion(10000 kcal) | 28-38.5 | 38.5-49 | 52.5-63 | 63-77 | 70-87.5 | 84-94.5 |

Traction motor power(kw) | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 |

Hot air fan power (kw) | 11*4 | 11*5 | 11*6 | 11*7 | 11*8 | 11*9 |

Air cooling fan power(kw) | 11 | 11 | 11 | 11 | 11 | 11 |

Total power (kw) | 66 | 77 | 88 | 99 | 110 | 121 |

Overall size LxWxH(m) | 20*4.5 | 24*4.5 | 28*4.5 | 32*4.5 | 36*4.5 | 40*4.5 |

1. The veneer after drying by Shine veneer dryer is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect.

3.Shine roller veneer dryer covers a small area, less ancillary equipment, convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4.Standardized production models, can make different sections or decks according to different capacity requirements, which can meet different customers' requirements.

5.Each section with heat exchanger, which can make full use of the heat and achieve the best drying effect.

6.All the fans are with converter motor, which can guarantee the service life of the dryer.

Company Profile and Shipment

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd