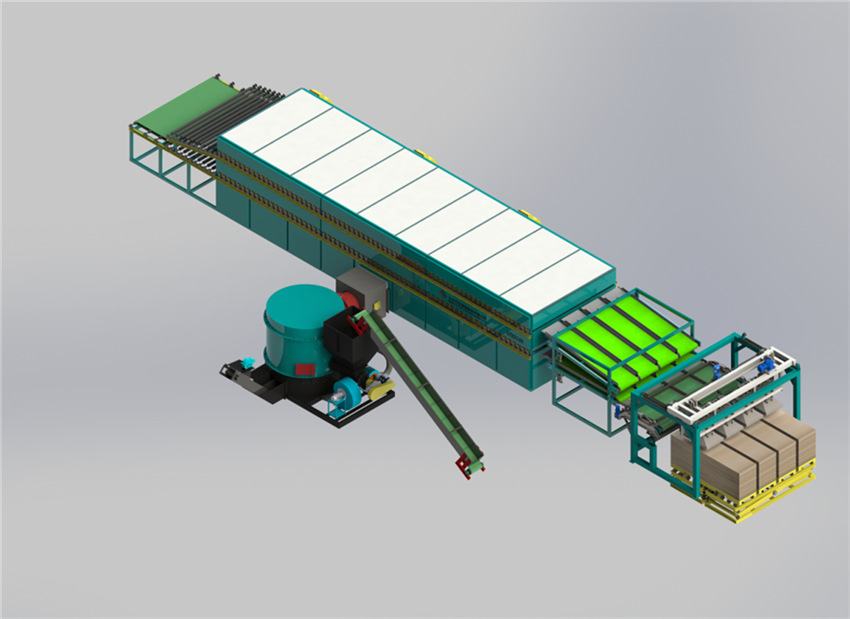

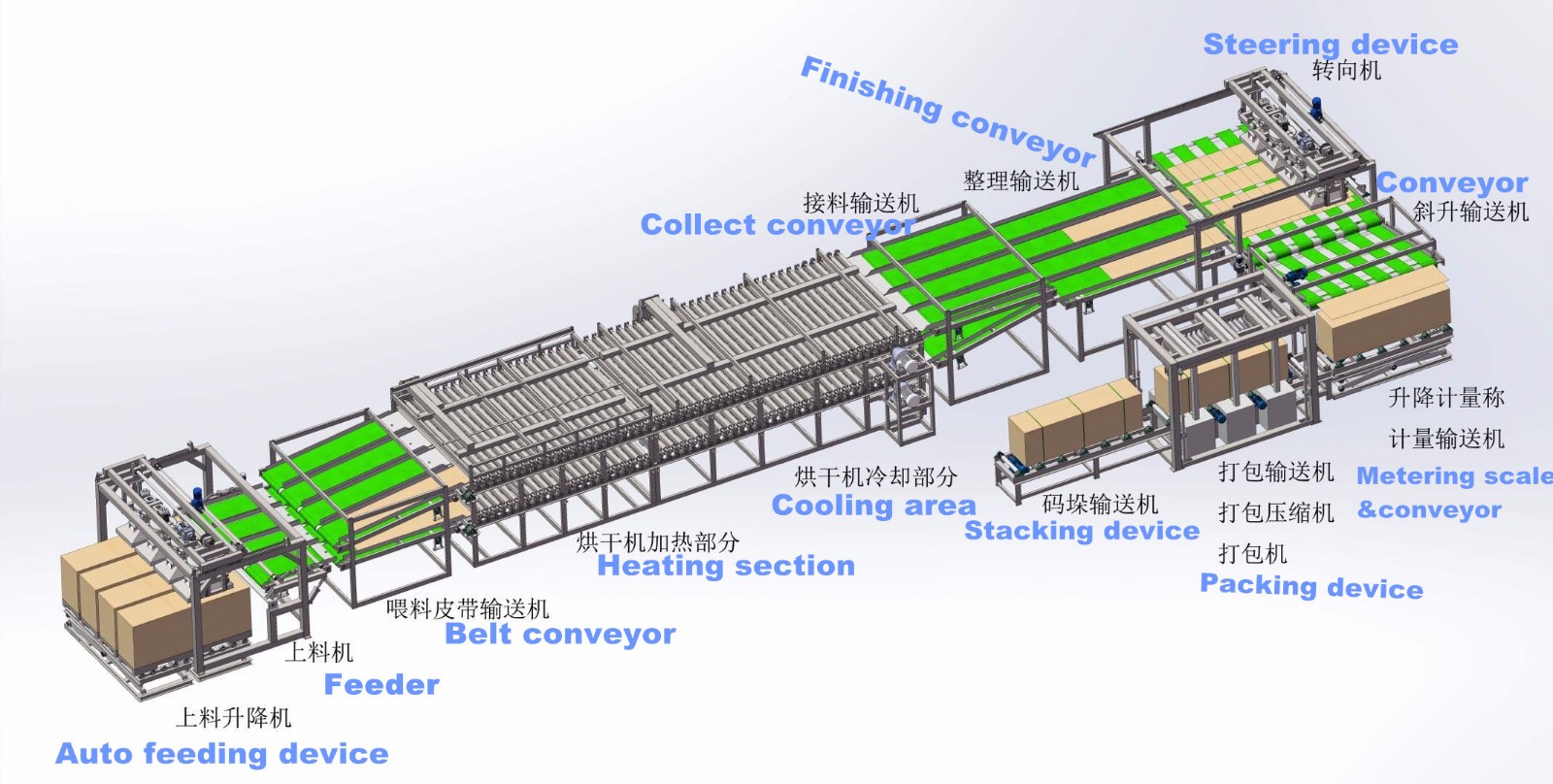

Shine Machinery never stopped its pace in pursuit of the veneer jet dryer innovation in the wood working industry. From one deck, double decks, to three and four decks veneer drying machine, the production capacity is bigger and bigger with the energy efficiency higher and higher. The fuel cost in drying veneers is the lowest compared to the steam/water boiler type drying veneers machine or thermal oil core veneer drying machine.

Main Technical Parameter for Shine Machinery is in Pursuit of Jet Dryer Innovation

Parameter Model |

DHS20M

| DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 2 | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 0.8-1.1 | 1.1-1.4 | 1.5-1.8 | 1.8-2.2 | 2-2.5 | 2.4-2.7 |

Heat exhaustion(10000 kcal) | 28-38.5 | 38.5-49 | 52.5-63 | 63-77 | 70-87.5 | 84-94.5 |

Traction motor power(kw) | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 |

Hot air fan power (kw) | 11*4 | 11*5 | 11*6 | 11*7 | 11*8 | 11*9 |

Air cooling fan power(kw) | 11 | 11 | 11 | 11 | 11 | 11 |

Total power (kw) | 66 | 77 | 88 | 99 | 110 | 121 |

Overall size LxWxH(m) | 20*4.5 | 24*4.5 | 28*4.5 | 32*4.5 | 36*4.5 | 40*4.5 |

Biomass Roller Veneer Dryer Packing and Shipment

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd