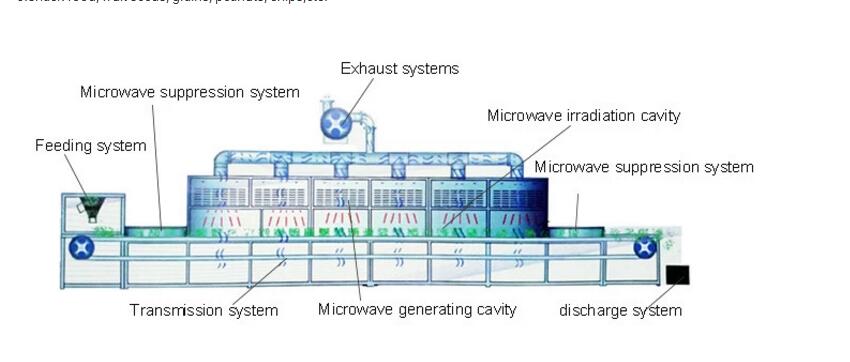

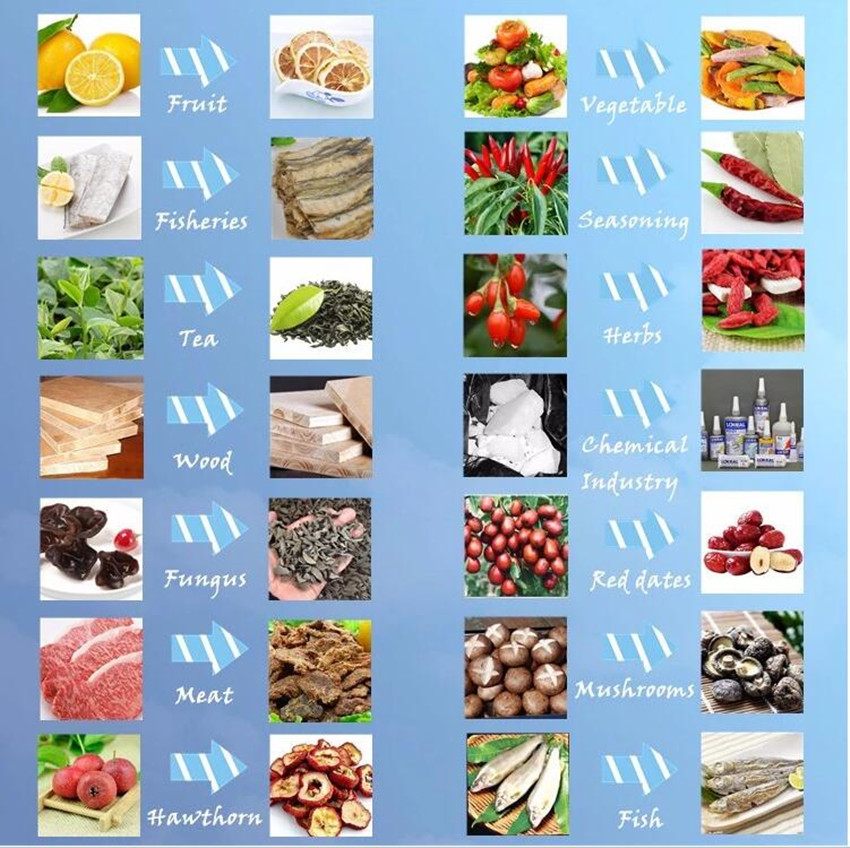

Except for drying green tea, the industrial microwave dryer is also can used for drying and sterilizing various kinds of food---snack food, agricultural products, fish slice, slice dried meat, bean products, instant noodles, fast food, dried fruit, tea, herbs, karaoke powder, fruit and vegetable in the form of powder, granules, slice, etc.It maximizes the preservation for activity of materials and vitamins, color & nutrition of food. It makes the goods drying and sterilizing at the same time. The principle of the microwave dryer equipment: the magnetron produce microwave, the microwave penetrate the material, the water molecule(hydrone) friction, getting the result of heating drying and sterilizing.

Model |

Working |

Input Power |

|

Overall Size |

Drying |

Sterilization |

SN12 | 2450MHz | 18kw | 12kw | 7.2x0.65x1.8m | 12kg/hr | 100-150kg/hr |

SN15 | 2450MHz | 20kw | 15kw | 8.3x0.72x1.8m | 15kg/hr | 120-180 kg/hr |

SN20 | 2450MHz | 26kw | 20kw | 8.5x0.75x1.8m | 20kg/hr | 180-250 kg/hr |

SN30 | 2450MHz | 36kw | 30kw | 10.5x0.95x2m | 30kg/hr | 280-350 kg/hr |

SN40 | 2450MHz | 46kw | 40kw | 10.5x1.05x2m | 40kg/hr | 380-450 kg/hr |

SN50 | 2450MHz | 58kw | 50kw | 12.2x1.2x2m | 50kg/hr | 480-550 kg/hr |

SN60 | 2450MHz | 68kw | 60kw | 13.5x1.2x2m | 60kg/hr | 500-600 kg/hr |

SN70 | 2450MHz | 78kw | 70kw | 13.5x1.55x2m | 70kg/hr | 700-800 kg/hr |

SN80 | 2450MHz | 90kw | 80kw | 15.5x1.55x2m | 80kg/hr | 800-900 kg/hr |

SN100 | 2450MHz | 110kw | 100kw | 16.5x1.75x2m | 100kg/hr | 1000-1200kg/hr |

1. High microwave heating speed: directly heat on the internal and external of material at the same time, do not need to preheat. While there must be a preheating process in the traditional production

2. Heating evenly: microwave drying is completed through electromagnetic waves produced by magnetron. The internal and external of material will be heated at the same time , no leaf scald , focal side, fragment and etc.

3. Less nutrition loss: material just stay in the microwave heating box for a short time, and do not need air and steam to conduct heat, therefore can maximize keep nutrients in the material.

4. Sterilization and alcoholization: there will be probably second pollution to the material during making process. This microwave drying equipment also have sterilizing and alcoholizing function.

5. Reduce the labor intensity, improve work efficiency: this equipment could finish feeding and baiting automatically. The operator simply press the button, monitor equipment operation condition and degree of killing out. The whole production only takes 1-2 people. While the traditonal takes 5 to 6 people.

6. Friendly environment equipment: this equipment will not create high temperature, dust and noise.

keywords: tea green removing m

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd