Shine 6 feet veneer peeling machine line is most common model veneer peeling machines in woodworking field. Normally the veneer peeling machine will be used together with veneer dryer machine. the working efficiency will be highly improved by Shine veneer peeling line and drying line .the main features and advantages of Shine 6 feet veneer peeling line:

1. With hydraulic system. Rotary peeling and cutting are all together.

2. The use of a Feeding Screw precision closed completely driven by servo motor Gear Reducer with hardened precision.

3. The thickness of the plate, the opening of the Knife can be adjusted automatically by itself.

4. With the Control System of the computer. The Plate thickness with a minimum margin of error of 0.05 mm

5. The last section of cut could Cut the sheet is for the full size.

6. Matched with the automatic stacker of the absorbability of vacuum.

7. The team is equipped with a circular system free of logs,

The Rotary Cutting Speed faster and more convenient.

8. Compact structure, stable performance, simple operation and High Efficiency and easy maintenance.

DESCRIPTION | UNIT | PARAMETERS |

Maximum diameter of conveying | mm | 600mm |

Linear speed of host machine | m/min | 30mm |

Transmission motor power | kw | 4kw+4kw |

Reducer type selection | Worm gear reducer

|

2.4 Feet excircle barking machine(milling type)

DESCRIPTION | UNIT | PARAMETERS | |

Length of barking log | mm | 1960mm—2100mm | |

Diameter of barking log | mm | Maximum 600mm—Core 100mm | |

Barking thickness range | mm | 1mm—4.0mm | |

Linear speed of host machine | m/min | 45m | |

The main auxiliary motor power | KW | 42.5kw | |

Reducer type | Host R helical gear reducer | ||

Main function | Outer round peeling of logs with bark and tree shrews | ||

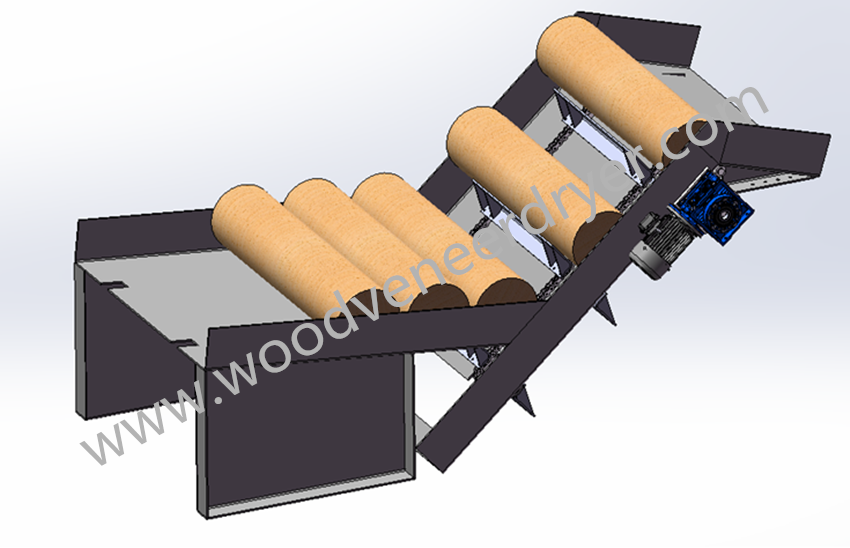

3.Log alignment machine

DESCRIPTION | UNIT | PARAMETERS |

Maximum diameter of conveying | mm | 600mm |

Linear speed of host machine | m/min | 30mm |

Transmission motor powr | kw | 1.5kw +1.5KW |

Reducer type | Worm gear reducer

|

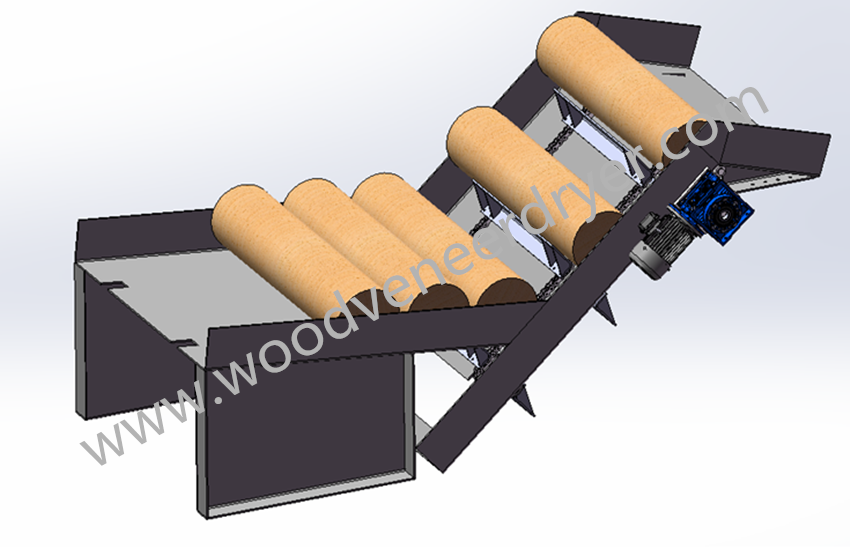

4.Feeding machine for peeler

DESCRIPTION |

UNIT |

PARAMETERS |

Maximum diameter of conveying | mm | 600mm |

Linear speed of host machine | m/min | 30mm |

Transmission motor power | kw | 4kw |

Reducer type | Worm gear reducer

|

5.High configuration peeling machine

DESCRIPTION |

UNIT |

PARAMETERS |

Length of peeler log | mm | 1970mm--2100mm |

Diameter of peeler log | mm | Maximum 500mm—Core 30mm |

Rotary cutting thickness range | mm | 0.5mm—4mm |

Linear speed of host machine | m/min | 45m –120(adjustable) |

The main auxiliary motor power | KW | Host7.5+7.5+7.5+7.5KW Feeding 11KW |

Reducer type | Host R helical gear reducer | |

Main function | 1.Peeling speed adjustable 2.Automatic trimming function of residual tail plate 3.Japanese SMC guideway cylinder is used to core and press the tail plate. 4. Alloy wire rod and tin bronze nut 5. Imported silver linear guide rail from Taiwan 6. Plate surface two side light function 7. the weight the machine is about 9ton | |

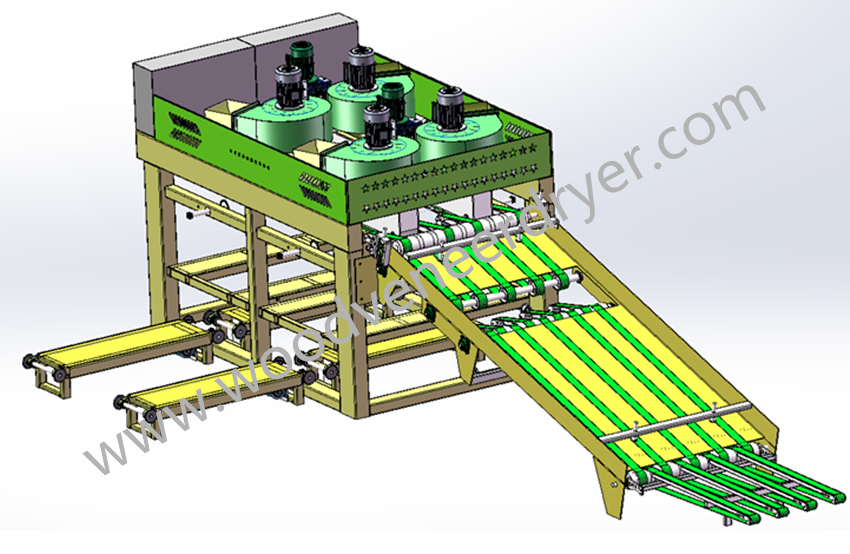

6.Vacuum absorption collecting machine

DESCRIPTION | UNIT | PARAMETERS |

Collect plate size | mm | 1300mm—2200mm |

The scope of thickness | mm | 0.5mm--- 4mm |

Linear speed of host machine | m/min | 120m adjustable |

vacuum absorption motor power | KW | 4kw=4pc |

Transmission motor power | kw | 2.2+2.2kw |

Lifting motor power | kw | 4kw |

Reducer type selection | Enlarged worm gear reducer |

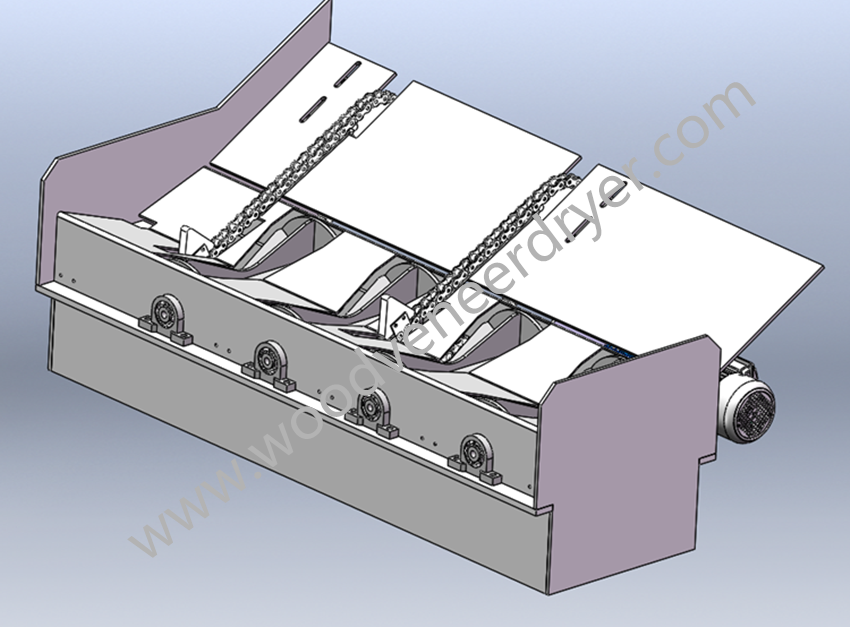

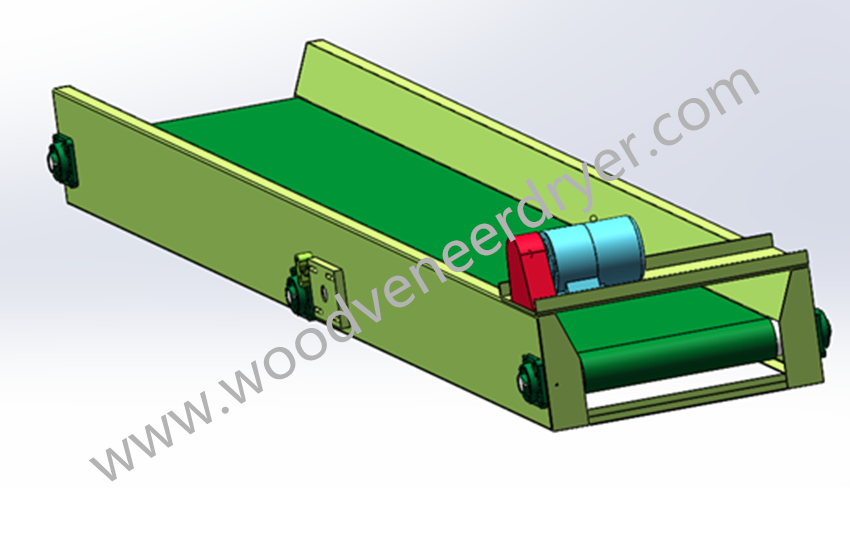

7. Garbage conveyor belt

DESCRIPTION | UNIT | PARAMETERS |

Garbage conveyor belt | mm | 4m |

Linear speed of host machine | m/min | 30mm |

Transmission motor power | kw | 1.5kw |

Reducer type

| Enlarged worm gear reducer |

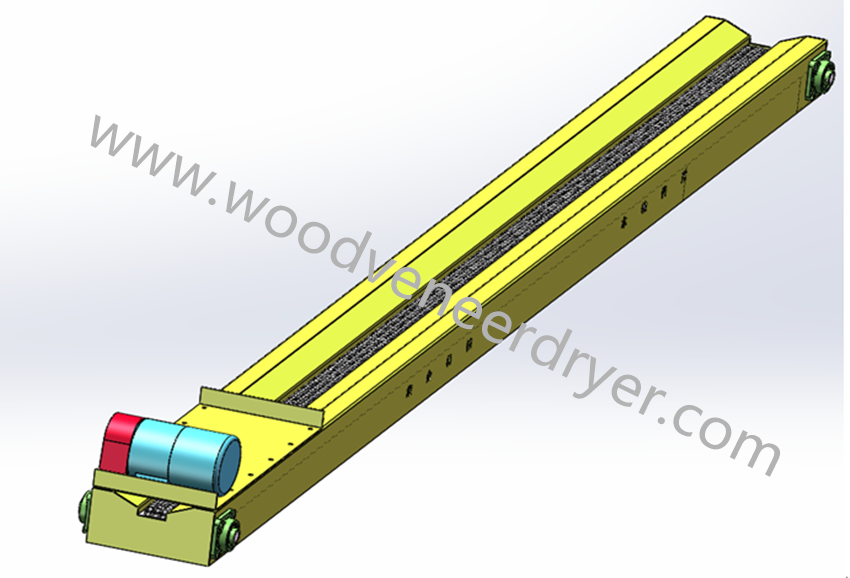

8. Wood core belt conveyor

DESCRIPTION | UNIT | PARAMETERS |

Core belt conveyor | mm | 4m |

Linear speed of host machine | m/min | 30mm |

Transmission motor power | kw | 1.5kw |

Reducer type selection | Enlarged worm gear reducer |

1. Q: Are you a factory or a trading company?

A: We are a factory who manufacture the machine by ourselves.

2. Q: What is the delivery time?

A: Normally will be 30 days after getting deposit or original LC.

3. Q: What is the maintenance period? What kinds of after-sale service do you support?

A: 1 year after delivery. We supply telephone after-sale service, video service and e-mail service. If can not deal with the problem, our tech-staff will go abroad to service.

4. Q:What is the payment terms?

A:a.T/T(30% deposit, 70% before delivery in FOB or 70% paid against copy of B/L in CFR)

b. 100% irrevocable L/C at sight.

5. Q: Can we visit your factory?

A: Welcome to visit us! Everyday we have customers from different countries. By now, we have exported to more than 50 countries customer.

Pre-sale services:

1) Provide the free consultation of the equipment

2) Provide the standard device and the flow chart

3) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

4) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Copyright By © Shandong Shine Machinery Co.,Ltd