Continuous Veneer Jet Dryer Introduction

The veneer sheets are continuously loaded into one end of the veneer jet drier, transported horizontally through the veneer drying machine, and unloaded (usually after passing through a cooling section at the other end of the veneer dryers. The sheets are oriented so their grain direction is parallel to their movement.

All the veneer driers used roller transport, i.e. the sheets move between pairs of horizontal driven rollers mounted perpendicularly to the direction of travel. They are constructed so the veneer is transported in a number of parallel layers, or decks, separated vertically from each other. The transport systems have a continuously variable speed drive which, when related to the length of the drier, provides control of drying time.

The driers are constructed of a number of similar sections, mounted side by side along their length. Each section contains a heating unit and an air circulation fan, and some contain, inlet and/or outlet air vents. Drying temperatures are normally over 100°C. The general air circulation is in a vertical plane perpendicular to the length of the drier. Plenum chambers are located each side of the drier. Air flows from the inlet plenum, through the drying chamber, to the outlet plenum, then returns over the top of the chamber.

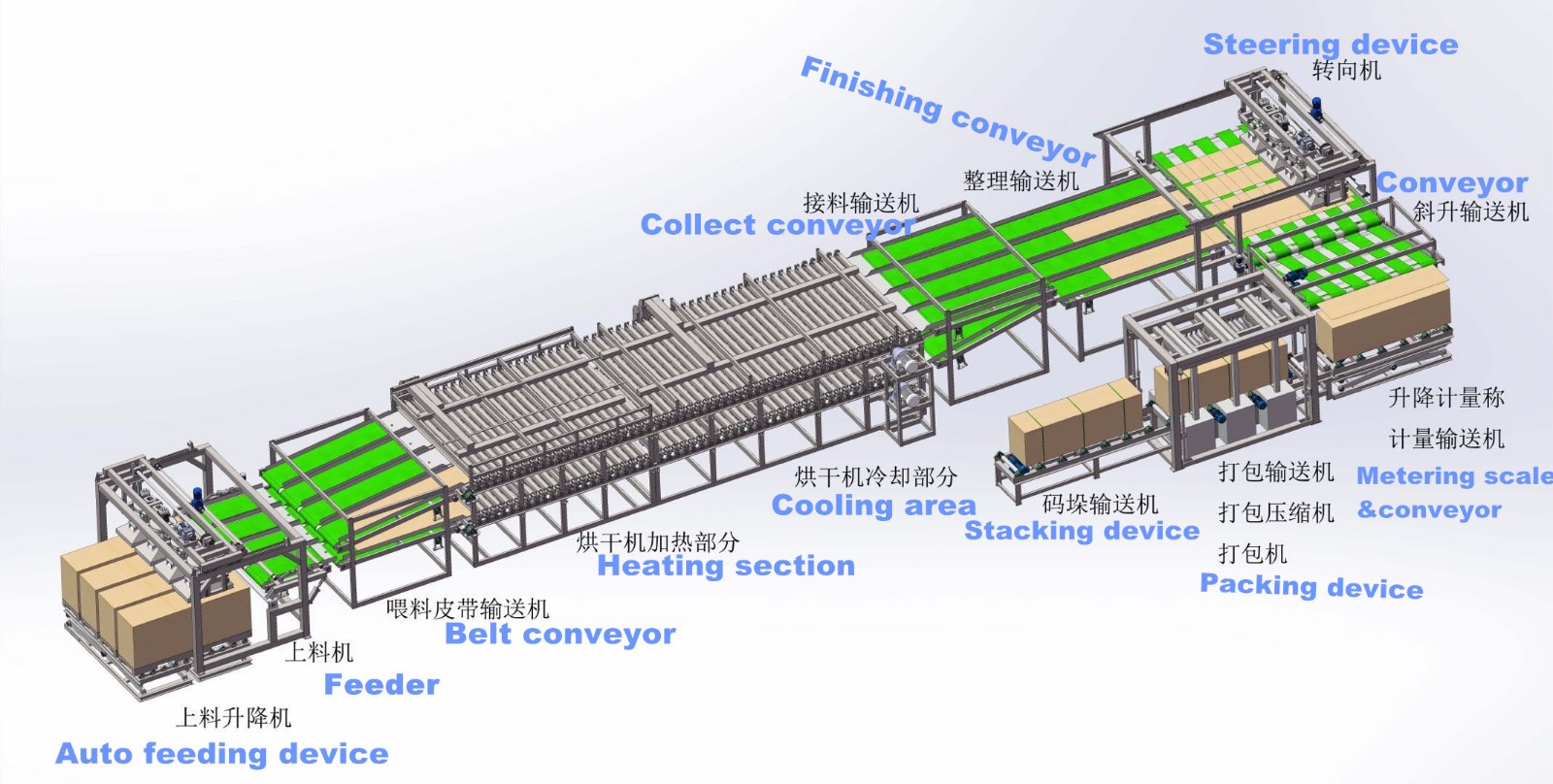

Continuous Veneer Jet Dryer Main Pictures

Technical Parameter for Continuous Veneer Jet Dryer

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Layer | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 2.7-3.1 | 3-3.3 | 3.2-3.5 | 3.5-3.8 | 3.8-4.1 |

Heat exhaustion(10000 kcal) | 94.5-108.5 | 105-115.5 | 112-122.5 | 122-132 | 132-143 |

Traction motor power(kw) | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

Hot air fan power (kw) | 11*10 | 11*11 | 11*11 | 11*12 | 11*13 |

Air cooling fan power(kw) | 11 | 11 | 11*2 | 11*2 | 11*2 |

Total power (kw) | 132 | 147 | 158 | 169 | 180 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd