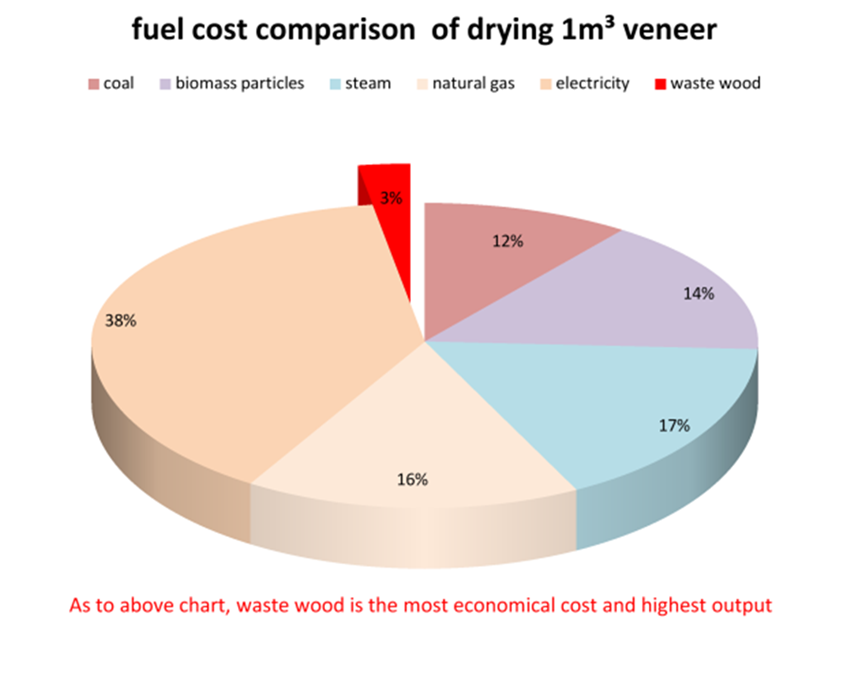

The wood veneer dryer can be used to dry core veneer and face veneer of rubber wood, eucalyptus, birch, teak, all kinds of hardwood and softwood veneer, etc. Shine veneer drying machine is renowned for consistently producing high-quality veneer with a uniform dry moisture content. The dried veneer by Shine veneer roller dryer has the uniform moisture content, flat with no buckle or end waviness, free of splits. The shrinkage is kept to a minimum. And the surface is in good condition before gluing for plywood making machine. Shine veneer dryers machine is equipped with biomass burner,which can burn waste wood directly and save drying cost mostly.Our core veneer dryer can design by professional team for user' special capacity requirements.

Parameter Model |

DHS20M

| DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 1 | 1 | 1 | 1 | 1 | 1 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 0.5-0.65 | 0.65-0.8 | 0.8-1 | 1-1.2 | 1.15-1.35 | 1.3-1.5 |

Heat exhaustion(10000 kcal) | 17.5-23 | 28-35 | 35-42 | 40.25-47.25 | 45.5-52.5 | |

Traction motor power(kw) | 7.5 | 7.5 | 5.5 | 5.5 | 5.5 | 5.5 |

Hot air fan power (kw) | 7.5*4 | 7.5*5 | 7.5*6 | 7.5*7 | 7.5*8 | 7.5*9 |

Air cooling fan power(kw) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Total power (kw) | 45 | 52.5 | 58 | 65.5 | 73 | 80.5 |

Overall size LxWxH(m) | 20*4.5 | 24*4.5 | 28*4.5 | 32*4.5 | 36*4.5 | 40*4.5 |

Company Information

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd