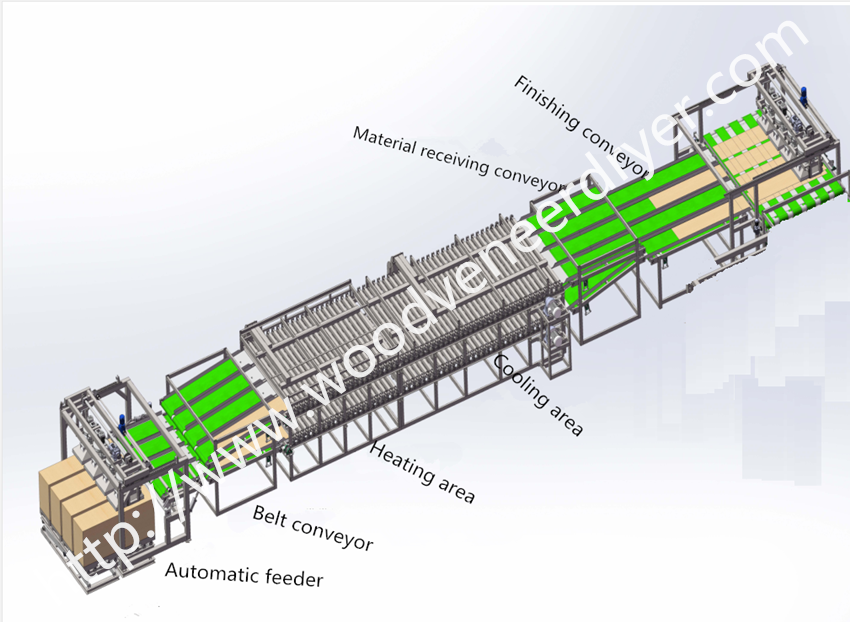

56m face veneer board dryer is one of the Shine roller veneer dryers. the capaicty of DHS56m face veneer board dryer is about 45-60cbm per day according to different moisture content of the plywood . The face veneer board dryer is made up of hot air stove, drying room, wood conveyor roller. According to different types of combustion media, they are divided into two types: And the equipment has the following features: small footprint, high thermal efficiency, high productivity, high operating costs. Coal-fired integrated dryers have a variety of combustion media. Leftover material of plywood, crop straw and coal produced waste can be used as fuel. The exhaust gas generated by the combustion cycle is circulated in the heat exchange box, it enters the furnace and burns again. After the heat exchange, hot air is blown into the air duct through the heat fan to heat the veneer, and only a small amount of smoke is exhausted. As the furnace body is integrated in the dryer, all the heat emitted from the furnace body and the flue gas ducts is collected and used, making it environmentally friendly and energy-efficient.

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Deck | 1 | 1 | 1 | 1 | 1 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 1.5-1.7 | 1.65-1.8 | 1.7-1.9 | 1.8-2 | 1.9-2.2 |

Heat exhaustion(10000 kcal) | 52.5-59.5 | 57.75-63 | 59.5-66.5 | 63-70 | 66.5-77 |

Traction motor power(kw) | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Hot air fan power (kw) | 7.5*10 | 7.5*11 | 7.5*11 | 7.5*12 | 7.5*13 |

Air cooling fan power(kw) | 7.5 | 7.5 | 7.5*2 | 7.5*2 | 7.5*2 |

Total power (kw) | 88 | 97.5 | 105 | 112.5 | 120 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

Copyright By © Shandong Shine Machinery Co.,Ltd