Rubber wood is common in Southeast Asia。Vintage veneer dryer features manual dryer speed control. The ability to modulate the veneer drying machine conveyor speed is not automatic and typically the dryer runs at a set speed, which may not be optimum for the wood species and thickness being dried. Shine rubber wood veneer dryer adopts the frequency conversion to adjust the veneer dryer line speed automatically in line with the variable thickness and moisture. By setting the correct speed, the amount of usable drying veneer is optimized. Without running at the optimum core veneer dryer speed, the wood may be too dry or not wet enough, and both have disadvantages, especially with respect to energy consumption. Wood that is too dry cannot be used for manufacturing as it may be too brittle and break. Wood that is too wet after drying requires a second pass through the dryer, effectively doubling the amount of heat energy that was required to dry a particular sheet of veneer.

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Layer | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 2.7-3.1 | 3-3.3 | 3.2-3.5 | 3.5-3.8 | 3.8-4.1 |

Heat exhaustion(10000 kcal) | 94.5-108.5 | 105-115.5 | 112-122.5 | 122-132 | 132-143 |

Traction motor power(kw) | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

Hot air fan power (kw) | 11*10 | 11*11 | 11*11 | 11*12 | 11*13 |

Air cooling fan power(kw) | 11 | 11 | 11*2 | 11*2 | 11*2 |

Total power (kw) | 132 | 147 | 158 | 169 | 180 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

Main Advantages of Shine Rubber Wood Veneer Drying Machine

1.Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect

2. The biomass burner is Shine patented product. It can burn all kinds of waste wood directly to reduce the drying cost to the most.

3. The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

4. The veneer after drying is free of splits and the surface is in good condition for gluing.

5. Shrinkage and casehardening is kept to a minimum and collapse and honeycomb are avoided.

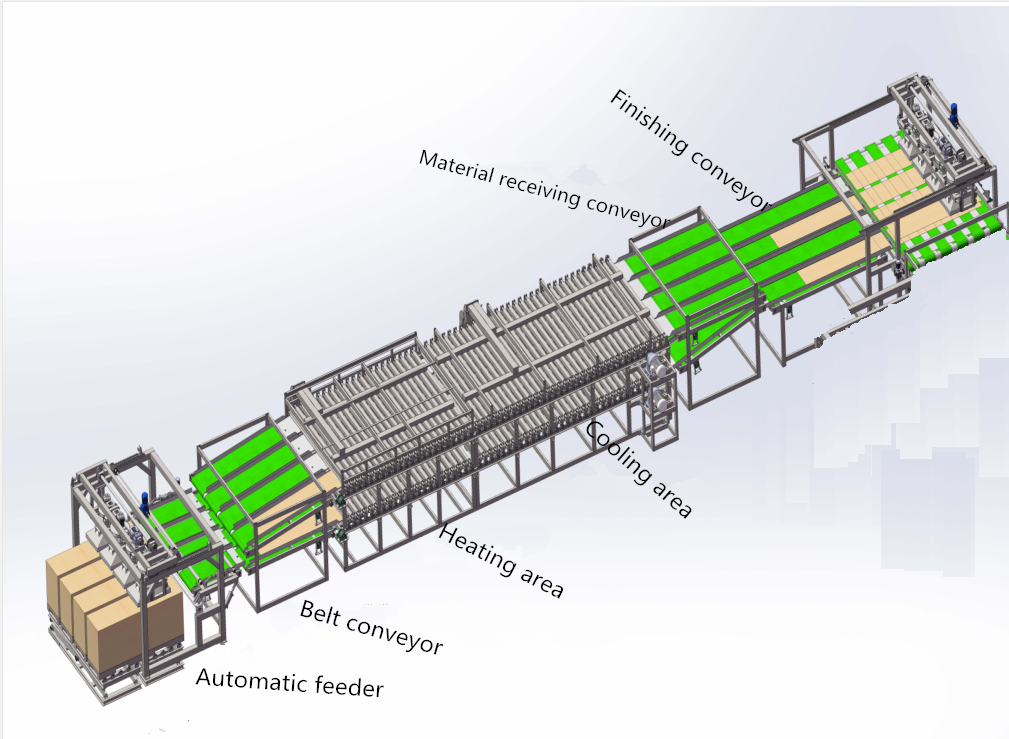

Shine Rubber Wood Veneer Drying Machine Pictures

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd